| Tension Test : The basic data on mechanical properties of a material are obtained by a tension test. Our mechanical division is equipment with electronically controlled tension test machine and data obtained from the tension test are plotted as a stress – strain diagram to determine tensile properties such as

upper yield strength ( ReH), lower yield strength (ReL,), Yield strength (0.2% offset) or 0.2% proof stress, ultimate tensile strength, % elongation and % reduction area. These specific tensile properties can be used for quality control, research and development, identification of unknown material, failure analysis, design and many other applications. Stress – strain diagram showing all important particular |

| |

| DMS has been performing tension test as per IS1608 reference to ISO6892 and both follow metric units. Tension test has also been performed as per A370 and ASTM E8 which are based on inch pound unit converted to metric units and ASTM E8M which is purely based on metric units. The stress controlled method has been employing to measure complete tensile properties. More recently a combined standard ASTM A1058 rationalized SI units and inch pound unit is followed. All these methods incorporate some variations in the area of test control and dimensional parameters which are given below. |

| |

| Parameter |

IS 1608/ISO6892-1 |

ASTM A370 |

ASTM E8/8M |

| Unit |

SI |

Inch-Pound converted to SI(mm) |

Inch Pound /SI |

| Gauge length |

5D |

4D |

4D/5D |

| Dimension <3mm, sheet |

12.5±1 or 20±1 or

GL =50 or 80 |

12.5±0.25 &GL=50 or sub size |

12.5±0.20 &GL=50 /62.5

or sub size |

| Dimension >5mm, plate |

12.5±1 or 20±1 or

GL =50 or 80 |

40+3/-6 & GL =200 or

40+3/-6 & GL =50 |

40±2 & GL =200

or 12.50±0.2 & GL =50 |

| Dimension >19mm, sheet |

Ø 20±0.15, 10±0.075

GL =50 or 100 |

Ø12.5±0.25 &

GL =50 or sub size |

12.5±0.20 &GL=50 /62.5

or sub size |

Speed for test

ReH(UYS), REl(LYS), Rp2

( YS 0.2% ) |

Stressing rate >6 N/mm2.S-1 <60 or straining rate >0.00025/s<0.0025/s |

Stressing rate >1.16N/mm2.s-1 <11.5

Straining rate <0.0003/s |

Stressing rate >1.15N/mm2.s-1 <11.5, Straining rate 0.015±0.006mm/mm/min |

| Rm (Su) |

Straining rate <0.008/s |

>0.05mm/mm/min <0.5 |

>0.05mm/mm/min <0.5 |

|

| |

| Mechanical Test |

Test Method |

Tensile Test

UTS, Yield, proof stress, %EL &%RA

Rockwell hardnesstest(HRC, HRB, HRA)

Brinell hardness test (HBW)

Vickers Hardness test (HV)

Bend Test

Rebend test on Tor steel

Compression test on spring

Flattening Test

Flaring Test

Proof load Test

Charpy Impact Test

IZOD Test

Upsetting test

Cupping test

Micro hardness test HV01-HV1

Case Depth by micro hardness

Decarburization depth by micro hardness

Shear Strenght |

ASTM A370, IS1608, EN10002

ASTM A370, ISl 586

ASTM A370, ISl 500

ISl 501

ASTM A370, ISl 599

IS1786

ASTM E384

ASTM A370, IS2328

ASTM A370, IS2330

ASTMA370&A194, IS 1367-(3&6)

IS 1757/IS0148

ASTM E23

IS1598

IS10167

IS 1501, ASTME384

IS 6416

IS 6396

ASTM A370 |

|

| |

| Stress - strain diagram of material with tensile strength of 630MPa(90ksi) are shown employing the above methods of tension test. All the above diagrams show similar results. |

| |

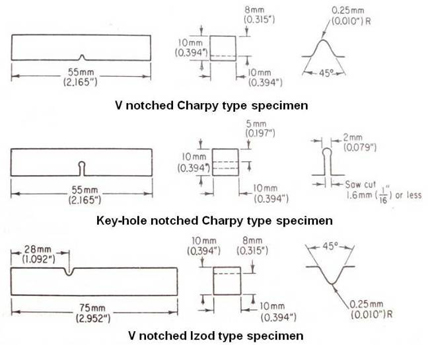

| Notched bar Impact test (Charpy & Izod): It measures the energy absorbed in fracturing a notched bar standard specimen under a single pendulum blow. The impact velocity of the pendulum is maintained between 5 and 5.5 m/sec. The specimen is forced to bend and fracture at high strain rate on the order of 103/s. The impact test is used to determine the toughness of a steel and tendency of material to behave in brittle manner under high strain rate dynamic fracture. This behavior may not be observable in a tension test. Our mechanical division is equipment Charpy impact test machine as per to ASTM E23 traceable to NIST and Charpy and Izod test as per IS 1757 machine traceable to ISO148-1. The Charpy impact test is conducted over a range of temperature from room temperature to sub zero temperature while Izod impact test is performed only at room temperature. |

| |

|

| |

| The Charpy impact specimen has 10x10mm square section with 55mm long and contains a V notch at centre and 2mm deep. The specimen is supported as a simple beam in horizontal position and loaded behind the notch by a swinging pendulum. The Izod specimen has 10x10mm square cross section with 75mm long and contains a V notch at 1/3distance from top and 2mm deep. The specimen is clamped as cantilever beam at V notch end and is fractured by a swinging pendulum in front of notch. |

| |

|

| |

| Steel having Body Centered Cubic structure (ferritic ) or Body Centered Tetragonal ( tempered martensitic) structure undergoes ductile to brittle transition temperature (DBTT). Many times, Charpy Impact testing is conducted over a range of temperature at which the ductile to brittle transformation takes place. |

| |

| There are three methods used to determine the DBTT such as FATT (Fracture appearance of transition temperature, absorbed energy with temperature and lateral expansion. |

| |

| FATT : In this method, the more precisely , the fractographic examination is carried out by Scanning Electron Microscope (SEM) to identify the mode of failure on the complete fractured surface of each impact tested specimen at regular temperature interval. The amount of shear dimple or equi axed dimple (fibrous) fracture and cleavage (granular fracture ) are determined. Normally a ductile to brittle transition temperature is obtained when fracture surface shows mixed mode of failure consisting of 50% shear and 50% cleavage. This method is commonly used for high strength low alloy steel having extremely high absorbed impact energy. |

| |

| Charpy impact test is used over a range of temperature so that the temperature at which the ductile to brittle temperature transition takes place can be determined as energy absorbed decreases with decreasing temperature but it is difficult to measure accurately the transition temperature. The absorbed energy is plotted against the test temperature maintained at an interval of 3 to 5degree from room temperature to subzero temperature. The sharp rise in absorbed energy is generally accepted as DBTT. |

| |

| Sometimes DBTT is defined as a particular absorbed energy value achieved at specific temperature, for example IS2062 E250 Grade C assures 27J at minnus 200C, EN10025 GradeS355 J2defines requirement of 27J at minus 200C and SA 516 Grade 70 is guaranteed for 20J at minus 450C. Carbon steel and alloy steels, a transition in ductile to brittle fracture occurs over a temperature range that depends on chemical composition and microstructure including prior austenite grain size of material; steel having finer grain size (ASTM No 5 to 8 ) absorbs higher energy than the coarse grain size (ASTM No 1 to 4). Since solution heat treated austenitic stainless steel of type 300 series do not undergo ductile to brittle transition temperature, DBTT is measured by an amount of lateral expansion which is normally fixed to 0.90mm. A material with lowest transition temperature is always preferred. |

| |

|