| |

| Services |

| |

Remaining Life Assessment |

| |

|

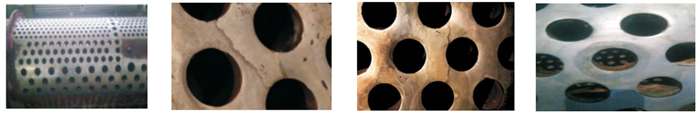

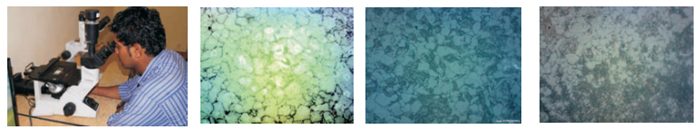

| DMS is also offering consultancy services including remaining life assessment (RLA) for boiler and boiler equipment of marine vessel (Indian naval ship); remaining life assessment of primary reformer tube, pig tails and allied equipment, secondary reformer. Steam turbine, urea stripper, pipe lines, furnace tubes, steam turbine etc. of fertilizer plant; replica metallography for condition assessment of large component and equipment exposed to high temperature such furnace tubes, steam turbine, super heater tubes etc. Besides, DMS has been utilizing the techniques that are used for remaining life assessment of boiler and boiler equipment are as follows: |

- Replica metallography employing Environmental Scanning Electron Microscope (ESEM), up to 10,000 magnification

- Replica metallography employing Optical Metallography, up to 1000magnfication

- Creep void and creep level assessment as per ECCC Vol. 6.

- Creep life assessment, hours by Larsen Miller Plot

- Creep assessment by dimensional measurement

- Super heater tube wall temperature by oxide scale measurement

- Analysis of scale deposits by PMI at site

- Ultrasonic flaw detection

- Dry or fluorescent magnetic particle inspection

- Dye penetrant inspection

- Onsite hardness

- Boroscopic examination

|

| |

| Level - I : On Site Metallography PT, MT, UT |

|

| |

| Level - II : Our specialized services include Surface Replications, Onsite Hardness, PMI, UT-Oxide Thickness, Metallurgical and Oxide analysis & Remote Visual Inspection. |

|

| |

| Level - III : Creep estimation, ECCC VOL. 6 - Fracture Mechanics, Engineering Studies |

|

| |

|

| |

|

|

| |

|